CAM Milling: Process, Materials Used, Advantages, and Challenges

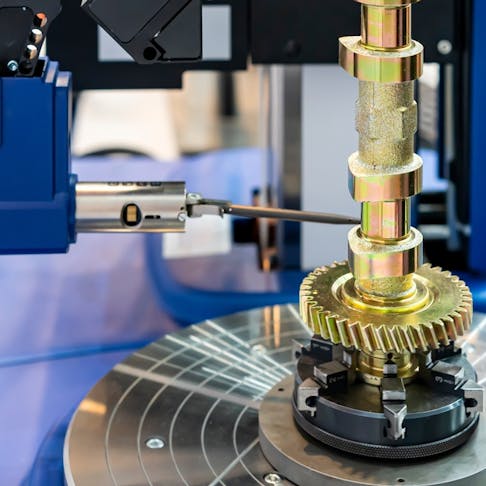

Computer-Aided Manufacturing (or CAM) milling, is a precision machining process that uses computerized controls to create complex pieces out of a variety of materials. Materials including: metals, polymers, and composites are often used. Because it can create complicated geometries with high accuracy, repeatability, and efficiency, CAM milling has many advantages.

Nevertheless, difficulties like tool wear and complex programming can occur. Through subtractive manufacturing, a CAM machine interprets digital design input and converts it into physical components.

This article will discuss CAM milling, its process, materials used, advantages, and challenges.

What Is CAM Milling?

CAM milling, a pivotal manufacturing method, synergizes milling and Computer-Aided Manufacturing (CAM) software for precision engineering. In milling, material subtraction occurs as a spinning tool shapes the workpiece. CAM software automates this on CNC machines, translating CAD designs into machine-readable code. CAD and CAM can be effortlessly integrated with technologies like Mastercam®. This dynamic combination guarantees accurate and economical production of finely designed components by optimizing the manufacturing process and improving precision.

How Does CAM Milling Work?

CAM milling transforms traditional manufacturing by automating processes through software. Designers create intricate 3D models with CAD software, while CAM software converts these designs into exact instructions for automated tools and machinery. Because the program interfaces directly with the manufacturing machinery, there is no longer a requirement for manual jig setups. Many thousands of identical models can be produced accurately and efficiently thanks to the streamlined method, which also drastically cuts down on labor and time. Productivity, consistency, and overall quality of manufactured goods are improved in a variety of industries by this CAD/CAM integration.

How Are Different Types of CAM Milling Processes Categorized?

The different kinds of CAM-milling operations are divided into groups according to the particular machining methods used. Considerations taken into account in this classification include: the machining direction, toolpath approach, and operational complexity. Face milling, pocket milling, and contour milling are examples of common classifications; each is suited to particular geometric shapes and specifications. Furthermore, high-speed machining, adaptive machining strategies, and multi-axis milling are examples of advanced CAM procedures that demonstrate the intricacy and adaptability of CAM technology in meeting a range of industrial demands.

Why Is CAM Milling Advantageous in Modern Manufacturing?

CAM milling offers several advantages in modern manufacturing as listed below:

- Decreases the likelihood of mishaps and injuries on the work floor using automated CAM systems.

- Guarantee high machining accuracy, meeting stringent tolerances.

- Automated processes decrease manual labor, enhancing overall production efficiency.

- Facilitates the creation of complex and intricate shapes with ease.

- The automated nature of CAM milling ensures uniform outcomes, minimizing variations.

- CAM machines operate at high speeds, contributing to swift production cycles.

What Factors Should Be Considered When Selecting Materials for CAM Milling?

The factors to consider when selecting materials for CAM milling include:

- Material Requirements: Consider functionality, strength, and operating conditions.

- Part Application: Tailor material choice to the specific needs of the application, such as weight requirements for aerospace parts.

- Environment of Operation: Ensure the material can withstand environmental conditions and machining heat.

- Stability in Dimensions and Tolerance: Choose materials with good stability and machinability for precise dimensions.

- Machinability: Factor in ease of machining, especially for large production batches.

- Physical Appearance: Consider aesthetics if important for consumer products.

- Material Costs: Balance functionality with costs, exploring viable alternatives when needed.

- Availability: Ensure selected materials are readily available for efficient CAM milling.

How Do Precision and Accuracy Impact CAM Milling?

Precision and accuracy are important in CAM milling to guarantee the creation of high-quality products. Precision is required throughout the whole machining process, from programming the machine to milling the pieces. Any departure from the intended level of precision may lead to defective products. This may render the finished item unsuitable for its intended purpose, and in doing so may damage the reputation of the maker. Excellence in CAM milling demands a steadfast dedication to upholding the highest level of accuracy at every step of the procedure.

How Has CAM Milling Technology Evolved Over Time?

Since the introduction of numerical control (NC) machines in the 1950s, CAM-milling technology has seen substantial evolution. Intending to accelerate industrial processes, John T. Parsons invented NC. A significant turning point was the creation of G-code, particularly by MIT in the late 1950s. This development made NC machine programming more accessible. Computer-aided manufacturing’s increased accessibility during the 1990s switch from UNIX to PC led to its eventual integration with CAD. The precision that modern CAD/CAM technology offers in a variety of techniques, including: milling, laser and plasma cutting, water jet cutting, and even 3D printing, has completely changed the manufacturing industry. More efficiency gains and perhaps the merging of engineers' and machinists' roles are in store for CAM milling in the future.

What Makes CAM Milling Different From Other Milling Techniques?

CAM milling distinguishes itself from other milling techniques through:

- Computer-Aided Control: With CAM milling, precision is increased through automated control systems that are directed by digital data.

- Integration with CAD: CAM milling seamlessly integrates with Computer-Aided Design (CAD), allowing direct translation of design data into machining instructions.

- Efficiency Emphasis: Through automated toolpath development and numerical control software, CAM milling puts efficiency first by optimizing the production process.

- Complex Geometries: CAM milling outperforms traditional milling processes in its ability to machine complicated shapes and elaborate designs with ease.

How Does CAM Milling Compare to Saw Milling?

CAM milling differs significantly from saw milling. While CAM relies on computer-aided precision and automation, saw milling involves cutting materials using saws, typically in a manual or semi-automated process. CAM's integration with CAD enables intricate designs and versatile tool use, enhancing precision and efficiency. In contrast, saw milling is often associated with simpler cuts and generally lacks the precision and complexity achievable through CAM. The evolution of CAM reflects advancements beyond the traditional methods associated with saw milling.

How Does CAM Milling Compare to Face Milling?

Face milling and cam milling are two examples of the various kinds of milling procedures. It is important to understand that cam milling and CAM milling are not the same. The technique that manages different milling processes, including face, pocket, and cam milling, to mention a few, is known as CAM milling. Cam milling is a milling procedure that uses a universal dividing head and vertical milling attachment to create cams on a milling machine.

Cams are usually eccentric lobes or protrusions on a spinning shaft with an irregular form. The procedure starts with the end of the dividing head spindle bearing the cam blank, and an end mill mounted in the vertical milling attachment. On the other hand, face milling is a type of machining in which a milling cutter with teeth on its face is used to create flat surfaces on the workpiece. A smooth and level surface is produced via face milling, which involves the cutter rotating perpendicular to the workpiece. This method is often used in the production of pieces that need to be precisely flat, such as: gearbox casings, engine blocks, and other sections in which an even and smooth surface is important.

To learn more, see our Face Milling Cutter guide.

What Are the Challenges in CAM Milling Operations and How Are They Solved?

Challenges in CAM milling operations and their solutions include:

- Costly Implementation: Invest in software, hardware, and machine tools while considering maintenance expenses.

- Training Requirements: Provide staff training for software and machine operation, ensuring skill updates.

- Data-Security Concerns: Safeguarding valuable data and designs from cyber-threats, theft, or corruption.

- Tool Wear: Implement regular tool inspections and replacements to maintain efficiency.

- Compliance: Adhere to legal and ethical standards in the industry and meet customer expectations for responsible CAM milling practices.

How Does Computer-Aided Design (CAD) Enhance CAM Milling?

CAD models, created in software like Autodesk Fusion, serve as the foundation for CAM operations. CAM software utilizes these models to generate toolpaths, instructing machine tools on how to transform digital designs into physical components. The seamless integration between CAD and CAM ensures accuracy, efficiency, and the translation of intricate designs into precisely machined products, optimizing the overall manufacturing process.

What Are the Future Trends in CAM Milling Technology?

The combination of CAD/CAM and digital progression is causing revolutionary changes in the future trends of CAM milling technology. There are two main directions that milling innovations are going: one is toward high feeds and low depths of cut to improve metal removal rates, and the other is toward very high speeds and low chip cross-sections, as observed in high-speed machining centers. Chip splitter inserts, for example, are one of the creative solutions that help ensure high productivity in milling operations by increasing table feed without vibrations. Moreover, industry developments are observing adaptable cutters including a universal pocket that can accept different insert forms and minimize tool changes. Extremely rigid clamping tools are improving tool-clamping rigidity, enabling very high feeds and speeds. Highly rigid clamping tools, exemplified by the introduction of 160 mm diameter face clamping with XPC spindle units, are enhancing tool-clamping rigidity, allowing for very high feeds and improved heat resistance.

What Safety Protocols Are Essential in CAM Milling?

Essential safety protocols in CAM milling include:

- Personal Protective Equipment (PPE): Mandate the use of safety gear like: goggles, gloves, and ear protection.

- Emergency Stop Mechanism: Implement easily accessible emergency stops for immediate halting of the milling process.

- Tool Inspection: Conduct regular inspections of cutting tools to identify wear or damage, ensuring replacements are timely.

- Ventilation: Maintain well-ventilated workspaces to mitigate exposure to fumes or vapors generated during milling operations.

How Does CAM Milling Contribute to Cost Efficiency and Economic Viability?

By optimizing production processes, CAM milling adds to economic viability and cost-efficiency. Accurate toolpath generation reduces waste material and improves resource efficiency. Automation speeds up production and lowers labor expenses, resulting in shorter lead times. Working with a range of materials also improves flexibility and lessens the requirement for specialist tools. When taken as a whole, these elements streamline processes and make CAM milling a financially viable option for contemporary manufacturing.

What Customization and Flexibility Options Are Available in CAM Milling Processes?

To fulfill a wide range of industrial needs, CAM milling techniques offer substantial customization and flexibility possibilities. Toolpath optimization makes it possible to precisely match machining tactics to particular designs. The capacity to work with a variety of materials improves adaptability and application opportunities. The utilization of multi-axis machining capability facilitates the creation of elaborate designs and complex geometries. Adjusting cutting settings is possible with variable speeds and feeds, which can accommodate different materials and needs. Smooth CAD integration makes it easier to make quick changes, which encourages a flexible and adaptable manufacturing environment.

Why Is Training and Skill Development Important for CAM Milling Professionals?

Professionals in CAM milling need to invest in training and skill development since it improves accuracy, productivity, and flexibility. Skilled operators can successfully troubleshoot, decrease mistakes, and improve toolpaths. Evidence suggests that when people receive ongoing training to stay up with developing technologies, they will produce better products with less material waste and more productivity. Put simply, a skilled CAM milling specialist makes a positive impact on increased operating efficiency and guarantees the best possible use of CNC milling equipment.

Why Is CAM Milling Important for CNC Manufacturing?

For CNC manufacturing to function well and save manufacturing costs, CAM milling is necessary since it speeds up the creation of assembly line equipment. With the help of CAD/CAM software's customization features, tabletop CNC mills may produce extremely specialized designs that guarantee accuracy and adaptability when fabricating components. The use of CAM enhances the efficiency of workflow, enables economical mass production, and highlights its vital role in propelling contemporary manufacturing capabilities.

To learn more, see our full guide on What is CNC?

Summary

This article presented CAM milling, explained it, and discussed its process and materials used. To learn more about CAM milling, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including casting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Copyright and Trademark Notices

- Mastercam® is a registered trademark of CNC Software, LLC.

- Autodesk Fusion® is a registered trademark of Autodesk, Inc., and/or its subsidiaries and/or affiliates, in the United States.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.