Choosing the Right Metal Process

CNC Machining, DMLS, Metal Binder Jetting, or Sheet Metal?

When it comes to building end-use metal parts, we offer a few options: CNC Machining, DMLS (Direct Metal Laser Sintering), Metal Binder Jetting, and Sheet Metal fabrication.

To help you select the right one for your next project, we put together a brief summary of these four processes, including the key benefits, available materials, lead times, and more.

As you read through this post, note that metal 3D printing and CNC machining are not mutually exclusive; they can actually complement each other. Many of our customers have DMLS parts machined to hit tighter tolerances or achieve certain finishes.

Key benefits: CNC machining offers high precision parts with a high-quality finish.

Materials: Aluminum, Brass, Titanium, Carbon Steel, Copper, Stainless Steel, plus others available

Best suited for projects that need:

- Production-quality materials

- Tight tolerances

- Production at scale (up to 10,000 parts)

- Custom finishes, including anodizing, passivating, plating, and powder coating

Tolerances: ±0.005″ – 0.001″, depending on customer specs

Lead Time:

- Milled: within 9 business days

- Turned: within 5 business days

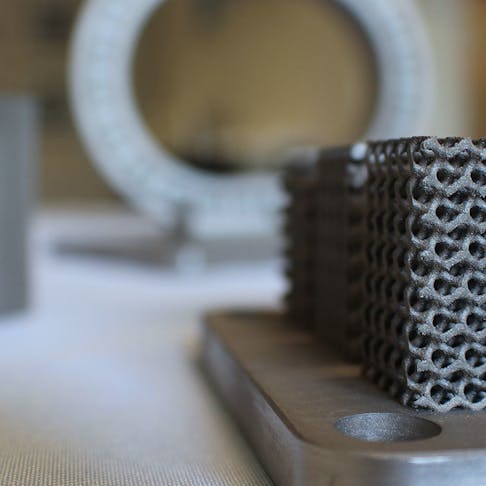

Key benefits: DMLS is capable of building complex geometries that otherwise wouldn’t be possible using traditional manufacturing. Additionally, metal sintered parts possess nearly the same strength and density as cast metal parts, but can be built in a fraction of the time.

Materials: Aluminum, 17-4 Stainless Steel, 316 Stainless Steel

Best suited for projects that need:

- Metal parts with complex geometries

- Aftermarket/replacement parts for legacy systems

- Low-volume parts and prototypes for functional testing

Max build volume:

- Stainless Steel – 9″ x 6″ x 6″

- Aluminum – 6″ x 6″ x 6″

Tolerances: ±0.005″ (can be improved through post-processing)

Lead Time:

- Stainless Steel: within 5 business days

- Aluminum: within 8 business days

Key benefits: Metal Binder Jetting is our least expensive 3D printing option for building custom metal parts. It also possesses high strength and abrasion-resistance properties.

Materials: Stainless Steel infiltrated with Bronze (60% 420 Stainless Steel, and 40% Bronze)

Best suited for projects that need:

- Low-cost, complex metal parts

- Parts that are too large for the DMLS build platform

- High abrasion resistance (e.g., thermal, chemical or mechanical stress)

Max build volume: 29″x 15″ x 14.25″

Tolerances: Parts can shrink during the binding process (approximately 1-2%)

Lead Time: within 13 business days

Key benefits: Sheet metal is capable of producing thin walled parts that are either not possible or not cost-effective to build via CNC milling.

Materials: Aluminum, Copper, Stainless Steel, Steel, Zinc

Best suited for projects that need:

- Thin metal walls

- Low-cost device panels, brackets, boxes, cases, and chassis

- Lightweight applications

Lead Time: within 12 business days