Tapped Holes vs Threaded Holes - Differences and Comparison

Learn more about the differences between these types of holes and the advantages of each.

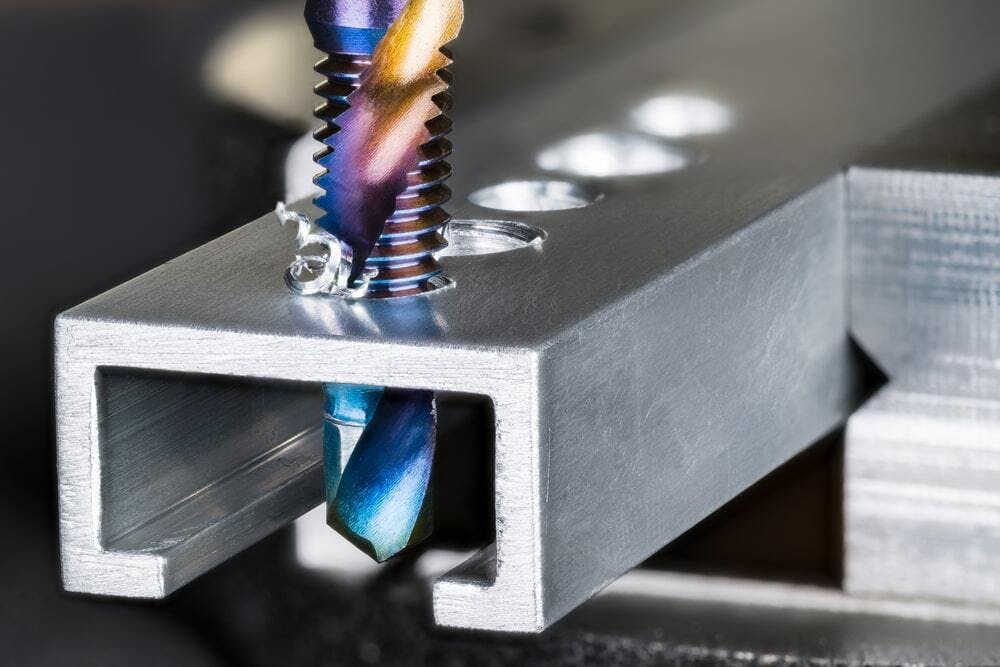

Tapping tool in spindle tapping into a hole in steel.

Image Credit: Shutterstock.com/Kachain Mungwattana

Tapped Holes Definition and Comparison to Threaded Holes

A tapped hole is a hole drilled before a machine screw is inserted. A tapped hole has threads cut into the hole’s inside exterior through the tapping process. A tapped hole is used in engineering with metals where a nut and bolt cannot be used. They hold threaded components with their internal threads, typically fasteners.

Compared to threaded holes, they are made differently. Tapped and threaded holes are similar but made by two different machining processes. The difference between threading and tapping is the tool used and the surface on which the processes happen. The threading process creates threads outside of a hole with a die tool. The tapping process makes threads inside a drilled hole with a tapping tool.

What Are the Advantages of Tapped Holes Compared to Threaded Holes?

An advantage of tapping compared to threading is speed. High-speed tapping centers with a rigid tap can thread holes in far less time than it would take to thread mill the same spots. Additionally, tapping can thread deeper holes in more rigid materials such as steel.

What Are the Disadvantages of Tapped Holes Compared to Threaded Holes?

One disadvantage of a tapped hole compared to threading is that a different size tap is needed for each size hole being threaded, consuming many valuable but limited positions in the tool magazine. Plus, having to switch tapping tools for each different-sized holes increases the cycle time.

The other disadvantage is that tapping doesn’t let the thread fit be adjusted. Once the hole is tapped, the thread’s size and position are final. Also, rigid taps are used only for the internal thread of holes.

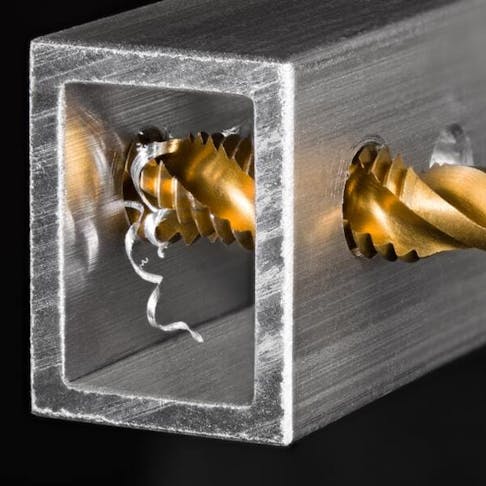

Closeup of tap and drill bit making a threaded hole in aluminum profile with metal shavings.

Image Credit: Shutterstock.com/KPixMining

Threaded Holes Definition and Comparison to Tapped Holes

Threaded holes are holes with threads that are created with a threading process using a die tool. They are similar to tapped holes but are made differently. In engineering, threaded holes are integral aspects of mechanically fastened parts. They are easy to add with CNC machines. Threads are usually added last after most other elements of the part have been machined.

The internal thread in a threaded hole can be either cut using a cutting tool (a cutting tap or single lip cutting tool) or formed using a forming tap.

The callout symbol for threaded holes is the ‘Ø’ diameter symbol, unless they are metic, in which case the diameter symbol is replaced with an ‘M’. Tapped and threaded holes are similar but made by two different machining processes. They are used for nuts, screws, and bolts.

The difference between threading and tapping is the tool used and the surface on which the processes happen. The threading process creates threads outside of a hole with a die tool. The tapping process makes threads inside a drilled hole with a tapping tool.

FREE CNC Machining Design Guide

What Are the Advantages of a Threaded Hole Compared to a Tapped Hole?

One main advantage of a threaded hole compared to a tap is controlling the fit. A threaded hole is milled at a high RPM. The drill tool helixes into an already made hole. So, the machine operator can adjust thread size using a strategy similar to an end mill rather than a drill bit.

Another advantage is that a single tool can be used in thread milling to make a wide range of hole sizes. This reduces tooling costs and time. In addition, a thread mill can create interior and exterior threads, right-hand and left-hand threads, and huge threaded holes. With large holes, using a single tool means engineers don’t have to invest in a large rigid tap.

A screw hand tap cutting tool.

Image Credit: Shutterstock.com/Tools navigation

Tapped Holes vs. Threaded Holes: Volume Comparison

Threading works better for high-volume production where different size holes or threads are required, as a single tool can be used for different sizes, so time doesn’t have to be wasted changing tools. In addition, various taps are available to match almost any screw-type, including metric and standard measurements.

What Are the Similarities Between a Tapped Holes and Threaded Holes?

The similarities between tapped holes and threaded holes are that they both contain internal threads for a fastener to fit into. They can also both be blind or through holes. A blind tap hole is when a tapped hole does not go completely through the workpiece. The thread part of the way through.

The thread sizes can vary with both types depending on the desired use. The two types are used when working with metal and machine screws, which cannot cut their own threads when driven into the workpiece.

Because metal is a stronger material, the screws thread cannot cut into it, so they must be inserted into a tapped or threaded hole. They both give extra grip to ensure that the screw stays in place.

Both processes are used for a bolt, screw, or nut.

Summary

This article provided a comparison between tapped and threaded holes and presented the advantages and disadvantages of each type.

Xometry provides a wide range of manufacturing capabilities and value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.