Compression Molding: Definition, Importance, How It Works, and Advantages

Learn more about how compression molding works.

Compression molding has been a longstanding and reliable manufacturing technique used across various industries. As technology and materials continue to advance, compression molding has evolved to meet the ever-changing demands of modern production. This article explores the advancements made in compression molding, exploring its benefits, limitations, and prospects.

What Is Compression Molding?

Compression molding is a manufacturing process that produces various plastic or composite parts. It involves placing a pre-measured and preheated material, such as a thermosetting polymer or thermoplastic compound, into an open mold cavity. The mold is then closed, and high pressure is applied to compress the material and shape it to the desired form. Heat is often used in conjunction with pressure to facilitate the curing or melting of the material. The combination of heat, pressure, and time causes the material to soften and flow, filling the mold cavities and taking on the desired shape. The pressure applied helps ensure that the material is evenly distributed and consolidated within the mold. Once the material has cured and solidified under pressure, the mold is opened, and the finished product is removed. The curing process typically involves the material undergoing a chemical reaction, such as cross-linking, which gives it its final strength and durability.

What Is the Importance of Compression Molding?

Compression molding finds application in processing pre-impregnated intermediate products to create semi-structural and structural composite components. Recently, compression molding has been adopted for platelet-like materials, which are fiber strands or bundles pre-impregnated with a thermoset or thermoplastic matrix. These materials bear similarities to waste thermoset prepregs or recycled thermoplastic materials.

Compression molding also allows for the production of large complex composite components with minimal material wastage. It is an attractive option for numerous industries seeking robust and cost-effective manufacturing solutions.

How Does Compression Molding Work?

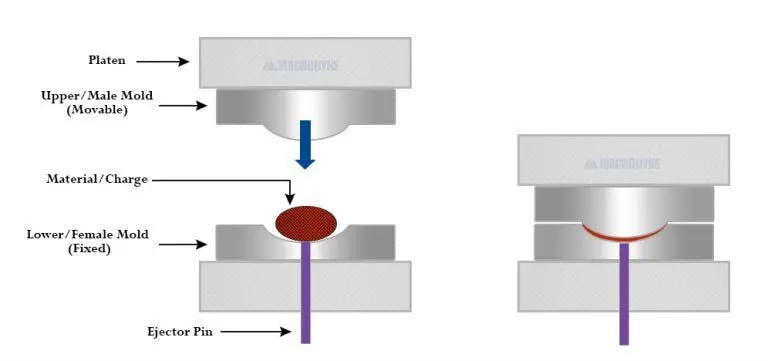

There are several steps involved in the compression molding manufacturing process. The first step is to create molds. These molds, typically made of steel or aluminum, are designed to meet dimensional and tonnage requirements. They consist of a cavity (space between the upper and lower mold) and an upper and lower mold as shown in Figure 1 below:

Compression molding process.

Image credit: https://macrodynepress.com/compression-molding-101/

Next, the machine is set up for the molding process. This includes cleaning the mold and, depending on the specific machine, turning on the heat to the mold. Temperature control is crucial in compression molding, especially for thermosets, to prevent defects and warping.

Material selection is important in compression molding. There are two main types: thermosets and thermoplastics. The processes for these materials share similarities but also differ in some aspects.

For thermosets, the process involves preparing the charge, which is typically a fiber-reinforced resin material but can also be rubber or silicone. The charge is placed in the heated cavity of the mold, and the mold is closed at a programmed speed and pressure. Under pressure and temperature, an irreversible chemical crosslinking reaction occurs, resulting in the curing of the part. After the part is cured, the pressure is released, and the part is removed from the mold. Any resin flash, or excess material around the edges, needs to be manually cut off.

For thermoplastics, the process is similar, but temperature-controlled cooling molds are used. Once the thermoplastic material hardens in the mold, it can be removed. In compression molding, thermoplastics are indeed melted before being introduced into the mold cavity. However, the process of filling the mold and ensuring complete coverage of the cavity with melted material is managed through the design and operation of the molding process.

How Long Does the Compression Molding Process Take?

Molding cycle times in compression molding are typically influenced by the thickness of the part being molded. However, they generally fall within the range of 60-300 seconds, making compression molding a fairly fast molding process for thermoset materials.

What Is the Equipment Used for Compression Molding?

Compression molding machines typically consist of the following:

- A large tonnage press, ranging from 150 tons to 2500 tons.

- A heated mold consisting of two halves, an upper and a lower, which are precision machined to create the desired shape of the final product. The mold cavities are designed to accommodate the material and allow for proper flow and distribution during the molding process.

- Separate heating chamber or an oven for the materials to be heated to a specific temperature to achieve their molten state.

- Long, slender cylindrical electric resistors known as heating lines as the primary heating elements.

- Shop air for cleaning purposes, such as removing debris or excess material from the mold cavity or part surfaces. Compressed air can be directed through nozzles or air blasts to blow away any loose particles or contaminants.

- Automation systems such as: conveyor systems, hoppers, or robotic arms, temperature control and monitoring devices, and mechanical ejection systems.

How Is Deformation Utilized in Compression Molding?

Compression molding relies on the deformation of a softened raw material pre-form under pressure and heat to force the material into the desired shape. It involves applying pressure or squeezing a malleable material charge between two halves of a heated mold. The material is then transformed into a molded part as it cools or undergoes curing.

What Are the Materials Used in Compression Molding?

Compression molding utilizes a variety of materials. Some of the most common materials used in compression molding are discussed below:

1. Epoxy

Epoxy resins are popular in compression molding due to their excellent mechanical properties, high heat resistance, and dimensional stability. They flow easily when melted, ensuring complete cavity filling during compression. The cured epoxy parts exhibit high strength and durability, making them ideal for applications requiring robust molded components, such as aerospace parts, electrical insulation, and structural composites.

2. Silicone

Silicone materials are well-suited for compression molding because of their exceptional temperature resistance, flexibility, and excellent electrical insulation properties. They can maintain their physical properties across a wide temperature range. Silicone material can easily flow and conform to intricate mold cavities, allowing for the production of precision seals, gaskets, medical devices, and automotive components.

3. Melamine

Melamine resins offer outstanding heat resistance, hardness, and chemical resistance, making them suitable for compression molding. Melamine molds easily and produces finished parts with excellent surface finishes and dimensional stability. Melamine is commonly used in compression molding for manufacturing kitchenware, decorative laminates, electrical components, and heat-resistant utensils.

4. Urethane

Urethane, or polyurethane, materials are favored in compression molding for their exceptional toughness, abrasion resistance, and impact strength. They can be formulated to exhibit a wide range of physical properties, making them versatile for various applications. Urethane flows well during compression molding, allowing for intricate mold designs and the production of items such as automotive parts, rollers, wheels, and industrial seals.

5. High-Density Polyethylene (HDPE)

HDPE is a thermoplastic material known for its high strength, chemical resistance, and rigidity. It can be easily melted and flows readily during compression molding, filling complex mold cavities with precision. High-density polyethylene parts exhibit excellent impact resistance and dimensional stability. Compression molding is commonly used for manufacturing products such as automotive components and industrial parts.

6. Polyphenylene Sulfide (PPS)

PPS is a high-performance thermoplastic with exceptional chemical resistance, flame retardancy, and dimensional stability. It has good flow characteristics when melted, ensuring complete cavity filling during compression molding. PPS parts exhibit high strength and stiffness, making them suitable for demanding applications in electrical components, automotive parts, and industrial equipment.

7. Polytetrafluoroethylene (PTFE)

PTFE is a non-stick fluoropolymer with exceptional chemical resistance and high-temperature stability. PTFE has a low coefficient of friction and excellent electrical insulation properties. It can flow easily during compression molding, allowing for the production of complex shapes and precise parts like gaskets, seals, bearings, and electrical insulation components.

What Are the Applications of Compression Molding?

Compression molding has a wide range of applications. Here are some of the common uses for compression molding:

1. Kitchenware

Compression molding is a commonly employed manufacturing method for creating various kitchen tools, utensils, and appliances. It is particularly utilized in the production of dinnerware items like bowls, cups, and plates, especially those made from melamine. Compression molding allows for the creation of different shapes while utilizing materials that offer heat resistance and hardness. The process produces sturdy products with excellent strength, making them suitable for daily use. Additionally, compression molding enables efficient mass production, making it a cost-effective choice for producing kitchenware items in large volumes.

2. Automobile Parts

Compression molding plays a significant role in the production of large parts and panels for automobiles, tractors, and other vehicles. This manufacturing process is commonly employed because it creates these components with precision and efficiency. Additionally, compression molding is used for manufacturing numerous plastic parts found in vehicle interiors, such as dashboards and door panels, as well as engine components.

3. Electrical Components

The process of compression molding finds frequent application in the manufacturing of electrical sockets, faceplates, metering devices, and switches. This method is a preferred choice for producing these components due to its ability to create precise shapes and ensure the necessary functionality and reliability required for electrical applications.

4. Video Games and Computers Devices

Compression molding is a commonly utilized technique for manufacturing various components of video game controllers, keypads, and other similar devices. It allows for the incorporation of materials with properties like impact resistance, dimensional stability, and electrical insulation. With its ability to achieve desired surface finishes and high-volume production, compression molding is an ideal choice for producing components that offer precision, durability, and user comfort in video games and computer devices.

5. Components for Medical and Dental Equipment

Compression molding is a prevalent method in the medical industry for manufacturing numerous plastic and silicone parts, such as respirator masks and syringe stoppers. This process enables the production of high-quality and precise components that are essential for medical equipment and devices.

What Is the Quality of Parts Produced Through Compression Molding?

Compression molding is known to produce high-quality parts. It is a manufacturing process that enables the production of high-volume parts with good dimensional precision, strength, temperature resistance, and surface quality. While no manufacturing process is entirely free from defects, compression molding typically yields parts with lower defect levels compared to other molding processes such as injection molding and transfer molding. Common defects that can occur in compression molding include flash, voids and porosity, uneven curing, and delamination. However, these defects can be minimized through proper mold design, precise temperature and pressure control, and material selection.

Are Compression-Molded Products Durable?

Yes. Compression molding produces durable products due to several key factors. First, the selection of thermosetting polymers in compression molding offers exceptional strength, rigidity, and chemical resistance. These materials undergo a chemical reaction during curing, forming a crosslinked network that enhances durability and stability. Additionally, the ability to include high fiber content, such as glass or carbon fibers, further improves mechanical properties like strength, stiffness, and impact resistance. The uniform distribution of material within the mold cavity ensures consistent mechanical properties throughout the part, minimizing weak points and potential failure areas.

Is Compression Molding Safe To Use?

Yes, compression molding is generally considered a safe manufacturing process when proper safety measures are followed. Some key procedures to follow include: wearing appropriate protective gear, including safety glasses, gloves, and heat-resistant clothing, performing regular maintenance and inspection of the compression molding machine, handling and storing raw materials according to the supplier’s instructions, furnishing good ventilation in the work area, and providing adequate training and education of personnel and operators.

Is Compression Molding in Demand?

Yes, not only is the demand for compression molding currently strong, but the global compression molding market is expected to continue to grow in the coming years. The compression molding machine market is expected to experience substantial revenue growth. The market is being fueled by increased investments in the manufacturing, infrastructure, and automotive sectors by both private and public entities on a global scale. These investments have led to a surge in demand for compression molding machines. As a result, the forecast period presents lucrative opportunities in the global compression molding machine market.

What Is the Lifespan of Compression Molding Products?

The lifespan of compression molding products can vary depending on several factors, including: the specific material used, the intended application, and the level of maintenance and care provided to the product. However, compression molding products are generally designed to be durable and long-lasting.

What Is the Future of Compression Molding?

The future of compression molding appears promising, driven by several factors that are shaping the manufacturing industry and the demand for advanced materials. Some trends and developments include:

- The development and utilization of advanced materials in numerous industries are expected to influence the future of compression molding. These materials, such as carbon fiber composites, bio-based polymers, and high-performance thermoplastics, offer enhanced properties, including strength, light weight, and sustainability.

- The integration of automation and digitization technologies is expected to streamline and optimize the compression molding process. Advanced robotics, machine learning, and real-time monitoring systems can enhance productivity, quality control, and process efficiency.

- Compression molding allows for the production of textured surfaces, and integrated features, such as ribs, bosses, inserts, fastening points, mounting brackets, and other functional components, with high precision. These features are typically molded directly into the part, ensuring their precise placement and alignment. Integrating these features during the molding process eliminates the need for separate manufacturing steps or joining techniques like welding or adhesive bonding.

- The versatility of compression molding in producing parts with superior mechanical properties, heat resistance, and dimensional stability makes it well-suited for sectors such as aerospace, electrical, and construction. Emerging applications such as electric vehicle components, 3D-printed molds, and medical devices are also expected to contribute to the future growth of compression molding.

What Are the Advantages of Compression Molding?

Compression molding offers several advantages that make it a preferred manufacturing process for various industries. Some of the key advantages of compression molding are:

- Produces parts with excellent strength and durability. The application of high pressure during the process ensures that the material is densely packed, resulting in robust and structurally sound products.

- Can accommodate varying thicknesses. The use of custom-designed molds enables the production of components with unique geometries, textures, and integrated features, such as ribs, bosses, inserts, and fastening points.

- Compatible with a wide range of materials, including both thermoset and thermoplastic compounds, to meet diverse application needs.

- Allows for the efficient utilization of material and reduces production costs. Compression molding is better suited for achieving consistent and efficient material distribution in thick-walled parts compared to injection molding and transfer molding. This efficiency in material utilization can lead to cost savings in terms of raw material usage and overall production costs.

- Typically produces parts with excellent surface quality. The application of high pressure during molding results in smooth and uniform surfaces.

- Enables batch production, allowing multiple parts to be molded simultaneously within a single cycle. The use of automated systems and advanced equipment further enhances productivity, reducing cycle times and increasing overall production output.

- Allows the use of recycled materials or bio-based resins, reducing reliance on virgin materials and promoting circular economy principles.

What Are the Disadvantages of Compression Molding?

While compression molding offers several benefits, it also has some disadvantages that should be considered. Some of these disadvantages include:

- Can produce complex parts, but not intricate internal geometries or thin walls. The use of a preform or charge, an open mold, and the pressure range limits the design freedom, making it more suitable for simpler shapes.

- Although it’s not a very slow process, compression molding typically has longer cycle times compared to other molding processes, such as transfer and injection molding. The combination of applying pressure, heat, and cooling cycles can result in longer production times per part.

- An important challenge associated with compression molding is the occurrence of flash, which can be problematic to manage if not adequately monitored and controlled. This issue may require additional processes such as manual trimming or nitrogen deflashing, which can incur extra costs.

What Is the Difference Between Compression Molding and Injection Molding?

The primary difference between compression molding and injection molding lies in how the raw plastic material is molded into the desired shape. In compression molding, the process involves applying high pressure and heat to the material within a heated open mold cavity. Conversely, injection molding employs molten plastic material, which is injected under pressure into a closed mold cavity.

Injection molding is well-suited for creating intricate and complex parts with thin walls, intricate geometries, and features like threads or undercuts. The molten plastic material is injected under high pressure into a closed mold cavity, allowing for precise and detailed part production. In contrast, compression molding is better suited for larger and more robust components with simpler geometries and thicker walls. The material is compressed within an open mold cavity, making it ideal for creating larger parts.

In terms of production speed, injection molding offers faster cycle times and higher production rates. The continuous injection of molten plastic material enables rapid and efficient production. Compression molding, on the other hand, involves a slower process due to material loading, compression, and curing time. For more information, see our guide on Molding in Manufacturing.

Summary

This article presented compression molding, explained what it is, and discussed its various applications. To learn more about compression molding, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including injection molding and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.